Abrasive wheels and metal cut off wheels are indispensable tools in industrial applications where cutting hardened steel is common. From construction sites to manufacturing plants, these grinding wheels provide precision, efficiency, and durability required to handle tough materials like hardened steel. Understanding the compatibility, techniques, and safety of using cutting wheels can vastly improve the performance and longevity of your tools. This comprehensive guide covers critical aspects of using cut off wheels, from choosing the right grinder blades for metal to employing advanced metal grinding wheels techniques that promise optimal results. Whether you are a professional in the field or a DIY enthusiast, the tips shared here will enhance your competence in handling hard steel cutting tasks.

The compatibility of cut-off wheels with different materials is a pivotal consideration in ensuring efficiency and safety during the cutting process. Selecting the right cut off wheel for grinder involves understanding the properties and limitations of grinding wheels for metal.

| Material Type | Compatible Wheel | Attributes |

|---|---|---|

| Hardened Steel | Steel grinding wheel | High durability, precision cutting |

| Aluminum | Aluminum cutting wheel | Prevents clogging, heat resistance |

| Stainless Steel | Inox cutting wheel | Corrosion resistance, reduced sparking |

| General Metal | Flap disc for grinder | Versatile, smooth finish |

Employing proper techniques is essential when using cutting wheels. Factors like cutting speed, angle, and pressure should be optimized to ensure effective results without compromising the integrity of the workpiece or tool.

Start by maintaining an appropriate cutting speed. Lower speeds reduce heat build-up while high speeds improve productivity. The angle grinder’s orientation should be adjusted between 15 and 30 degrees for optimal performance and safety. Practicing consistent pressure application across the entire surface of the metal grinding tools ensures an even cut, reducing the likelihood of uneven wear and tool damage. Using the right size is also important; for example, 7 inch metal grinding discs are widely used for versatile cutting tasks in industrial settings.

Safety is paramount when using abrasive grinding wheels. Implementing necessary precautions can prevent accidents and enhance the lifespan of the tools.

Firstly, equip yourself with personal protective equipment such as goggles, gloves, and ear protection to safeguard against debris and noise. Secondly, regularly inspect the metal wheel cutter for any signs of wear or damage. Replace worn-out wheels immediately to avoid compromised performance.

Finally, ensuring the work area is clean and free from potential hazards like loose debris or liquid spills can significantly mitigate risk. Also, avoid applying excessive force or sideloading the cutting wheel metal, which can lead to shattering or mechanical failure.

Although cut off wheels are highly effective, alternative tools could offer similar or enhanced benefits depending on the application. Grinding disc for metal and abrasive flap wheel are viable options for metal processing tasks.

A flexible grinding disc can adapt to various surfaces, making it ideal for complex shapes and contours. Additionally, flexible grinding wheels provide better control and reduce material wastage during finishing processes.

For projects involving stone materials, sourcing from reputable stone cutting disc suppliers ensures quality and durability.

A flap sanding disc can provide a smoother finish and is excellent for deburring, while a die grinder grinding wheel can reach tight spaces inaccessible to larger wheels. Understanding each tool’s specific strengths and limitations will allow you to choose the best device for your particular project needs.

To maximize the effectiveness of angle grinder cutting discs, adhere to the following tips and best practices:

Regularly clean the grinding wheel manufacturers tools to ensure longevity and efficiency.

Choose a 40 grit flap disc for coarse tasks and 120 grit flap disc for fine detailing.

Perform routine maintenance by checking and adjusting the angle grinder grinding disc ensuring tight and secure fitting.

Utilize the aluminium cutting wheel for softer metals to avoid wheel clogging.

For specific applications requiring color-coded identification, the green cutting wheel is known for its heat resistance and durability.

Enhancing your knowledge and application techniques regarding cut off wheel usage can significantly impact your efficiency, product quality, and safety outcomes.

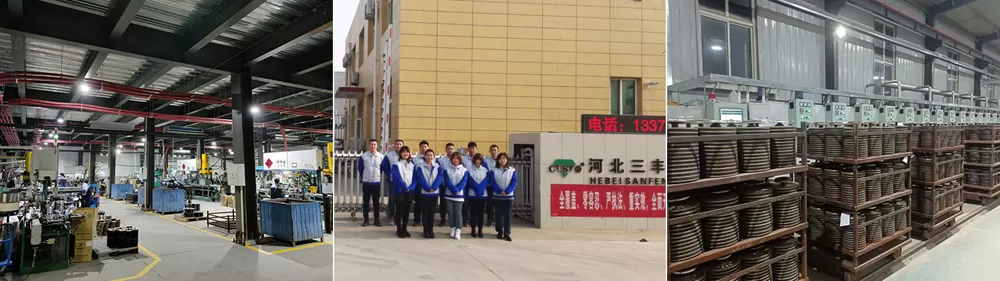

For optimal performance and safety in cutting hardened steel, partnering with a specialized cut-off wheel manufacturer is essential. Hebei Sanfeng Abrasives Co., Ltd. has been a leading name in the abrasive tools industry since 1997, with a strong focus on producing high-quality cut-off wheels tailored for demanding metal cutting applications.

As one of the superior abrasive wheel suppliers, Sanfeng’s expertise in cut-off wheels is backed by advanced Italian technology introduced in 2005, enabling the company to manufacture fiber reinforced resin sheet grinding wheels and cutting wheels with superior durability, precision, and safety. Their products are engineered to meet the rigorous requirements of cutting hardened steel and other tough metals, ensuring consistent performance and extended tool life.

The company’s large-scale production facility, equipped with state-of-the-art machinery and a dedicated R&D team, allows Sanfeng to innovate continuously and maintain strict quality control. Sanfeng’s cut-off wheels comply with national and international standards, including ISO9001 and EU MPA certification, reflecting their commitment to quality and safety.

Sanfeng’s cut-off wheels are widely used across automotive, marine, construction, and industrial manufacturing sectors, trusted by clients worldwide. With exports to over 20 countries and a reputation for reliability, Sanfeng stands out as a professional partner for businesses seeking high-performance cut-off wheels that enhance cutting efficiency and safety.

Choosing Sanfeng means choosing a manufacturer with deep technical strength, rich production experience, and a proven track record in delivering cutting wheels that meet the toughest industrial demands.