Flap wheels, also known as flapper wheels, are versatile abrasive tools consisting of overlapping abrasive flaps bonded to a central hub. These tools are ideal for contouring, blending, and polishing surfaces, offering a consistent finish without gouging the material. Unlike traditional grinding wheels, abrasive flap wheels provide flexibility and adaptability, making them perfect for irregular shapes and hard-to-reach areas.

As one of the leading abrasive wheel suppliers in China, Sanfeng designs, manufactures and sells flap wheels that incorporate advanced fiber-reinforced resin technology introduced from Italy in 2005. This ensures high strength, wear resistance, and safety, compliant with ISO9001 quality standards and EU MPA certification. Whether you're searching for abrasive flap wheel for metal or abrasive flap wheel for stainless steel, our products deliver exceptional cutting efficiency and longevity.

Choosing Sanfeng's abrasive flap wheels means investing in tools that enhance productivity and reduce costs. Here are the key advantages:

Superior Durability: Fiber-reinforced resin construction resists wear, extending tool life and minimizing downtime.

Efficient Grinding: High grit density, such as the 80 grit flap wheel series, allows for faster material removal. Our abrasive flap wheels for metal and stainless steel deliver consistent performance, maintaining their cutting power throughout their lifespan..

Versatile Applications: From rough grinding to fine polishing, our flap wheels adapt to various speeds and pressures on angle grinders.

Safety and Compliance: Certified for quality and safety, reducing risks in high-demand environments like foundries.

Competitive Flap Wheel Price: We offer bulk pricing without compromising quality, making us a preferred flap wheel supplier for global markets.

Our products have been exported to over 20 countries in North America, the Middle East, Southeast Asia, and Africa, earning a reputation for reliability and performance.

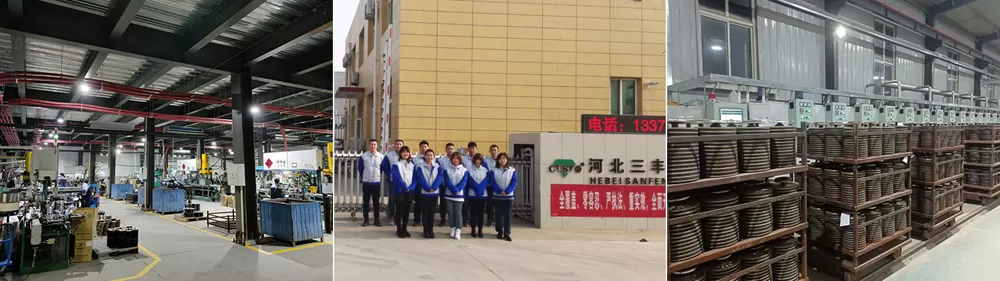

Founded in 1997, Hebei Sanfeng Abrasives Co., Ltd. stands out as a pioneer in abrasive tools, with over 25 years of expertise in resin grinding wheels. Our 20,000 square meter facility, equipped with cutting-edge Italian technology and rigorous quality controls, positions us as one of China's largest flap wheel manufacturers.

Technical Strength: 5 R&D personnel and advanced testing equipment ensure innovation and quality.

Global Reach: Exported worldwide with a focus on honesty, innovation, and customer satisfaction.

Commitment to Excellence: Strict adherence to national standards, with all products reaching advanced domestic and international levels.

Partner with us for reliable abrasive flap wheels, exceptional OEM service, and unbeatable value. Contact us today to discuss your requirements and secure your position in a competitive market.

As an experienced flap wheel manufacturer, we provide tailored solutions to match your exact specifications. Our professional team collaborates closely with clients to recommend the best custom abrasive wheels based on processing needs and equipment.

Customize Products: Adjust hardness, strength, wear resistance, grit size, and more. We offer customization from production to packaging, including color printing, trademarks, and custom patterns on inner/outer boxes.

Customize Process: From technical evaluation and scheme design to manufacturing, quality inspection, and delivery, we ensure seamless service.

After-Sales Support: Quick response to needs, including product replacement, for efficient post-purchase care.

Whether you need specialized China flap wheels for unique applications or bulk orders at competitive flap wheel prices, our 200+ employees and advanced facilities guarantee top-tier results.

Flap wheels are versatile abrasive tools primarily used for surface preparation, finishing, and light material removal in various industrial applications. They excel in conforming to irregular shapes and providing a consistent finish without gouging the workpiece. Common uses include:

Shaping and Contouring Metal: Ideal for blending welds, smoothing edges, and shaping metal surfaces in welding, machining, and heavy-duty equipment operations.

Deburring and Polishing: Effective for removing burrs from castings, polishing surfaces, and reducing surface contamination, often as an alternative to wire wheels.

Grinding Hard-to-Reach Areas: Suitable for internal surfaces like pipes or tubes, where flexibility is key for accessing contours.

Blending, Finishing, and Polishing: Used to achieve smooth finishes on metal, stainless steel, and non-metallic materials, including removing rust, paint, and weld seams.

Industry-Specific Applications: Widely applied in shipbuilding for hull preparation and rust removal; foundries for smoothing molds and deburring castings; automotive for bodywork, engine parts, and chassis finishing; as well as agriculture, food production, industrial maintenance, petroleum, chemical, and construction sectors.

Flap wheels are particularly favored for their ability to cut faster than traditional methods while minimizing burnishing, making them efficient for both coarse grinding and fine polishing tasks.

Grinding wheels and flapper wheels are both abrasive tools, but they differ in design, aggressiveness, finish quality, and ideal applications.

| Aspect | Grinding Wheel | Flap Wheel |

|---|---|---|

| Design | Solid, rigid wheel made of bonded abrasive grains (e.g., aluminum oxide) in a vitrified or resin bond. Typically thicker and less flexible. | Layered flaps of abrasive cloth (coated abrasives) overlapping on a backing plate or hub, providing flexibility and self-sharpening as flaps wear down. |

| Aggressiveness | More aggressive; removes material faster and deeper, suitable for heavy stock removal, cutting, and deburring hard materials like stone, steel, or tools. | Less aggressive; focuses on controlled removal with a smoother action, better for blending and finishing without deep gouging. |

| Finish Quality | Produces a rougher surface, often requiring additional steps for smoothing. | Delivers a finer, more uniform finish due to the layered flaps that expose fresh abrasive as they wear. |

| Flexibility & Contours | Less adaptable to curved or irregular surfaces; can cause overheating or burnishing if not used carefully. | Highly flexible, excels on contours, edges, and uneven surfaces like welds or pipes. |

| Durability & Cost | Wears down more slowly but can be more expensive long-term if frequent replacements are needed; requires more skill to avoid damage. | May wear faster during heavy use but lasts longer in finishing tasks; generally more forgiving for beginners and cost-effective for precision work. |

| Best For | Heavy-duty grinding, sharpening tools, and applications needing rapid material removal on flat surfaces. | Light grinding, deburring, polishing, and achieving smooth finishes on metals, especially in welding or fabrication. |

In summary, choose a grinding wheel, such as the flexible grinding disc, for tough, high-volume removal where finish isn't critical, and opt for a flap wheel when a polished result and ease of use are priorities.